Nova AncoFlex™

Fully automated analysis for PCB and IC-substrate manufacturing environments

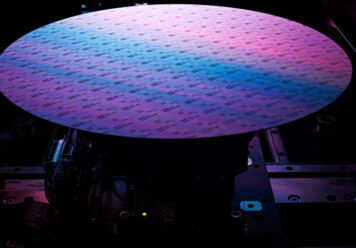

Nova AncoFlex® is an industry-standard fully automated inline chemical metrology solution for copper PCB and IC-substrate production processes. The solution supports a continuously growing range of copper baths and applications and provides excellent lifetime monitoring of bath composition and performance. The platform combines reported and controlled accuracy and precision with uncompromising reliability and the highest availability.

Highlights and Benefits

Fully Automated

Low Cost of Ownership

Data Access

Network Integration

Smaller Footprint

Fully Automated

Low Cost of Ownership

Data Access

Network Integration

Smaller Footprint

Fully Automated

Automates process analysis and carries out self-monitoring and diagnostics for failure detection via automatic validation and calibration

Low Cost of Ownership

High reliability with minimal service needs and long parts lifetimes for a low cost of ownership

Data Access

Maintains complete access to collected data for better characterization, troubleshooting, and process improvement

Network Integration

Communicates with all plating tools, and fully integrates with the fab communications network

Smaller Footprint

Optimally designed to require only front access for reduced required fab space

What is Nova AncoFlex®

Related Products and Technologies

You Might be Interested in

Demonstrating a DNA of InNOVAtion

Nova– a Journey of Innovation

How Did the Name Kaufman Turn into a Synonym to InNOVAtion at Nova?

Press Releases

ancosys Chemical Metrology Solution Selected by Additional Front-End Customer

Nova Expands Into Advanced Chemical Metrology With ancosys Acquisition

Nova Completes Acquisition of ancosys